|

Your path =Home>Beadmaking and Materials>Beadmaking, Glass > wound

Manufacture: Glass, Wound

Background

Twisting hot glass around a rod (called a mandrel) is the oldest and most universal way to make a glass bead. The first beads were made this way and several winding techniques are still used today.

|

|

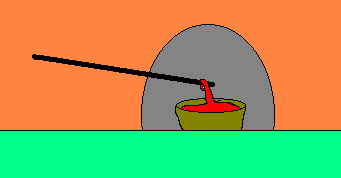

Furnace Winding -- The traditional way is to dip an iron mandrel into glass in a crucible in a furnace. A peak is used to wind the glass around the mandrel. The bead can be shaped or decorated. After its final heating, it can be knocked off the mandrel because iron cools faster than glass.

|

|

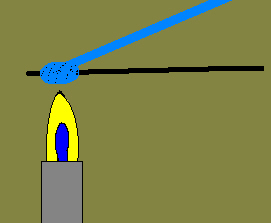

Lamp Winding -- More sophisticated is to heat prepared glass rods (canes) at a small lamp and wind the glass around a wire. This allows for more complex decoration. It is a newer art, few Venetian beads were made this way before about 1750.

|

|

|

|

Wound Beads -- However made, wound beads have their fabric encircling the perforation. The yellow bead is from Hebron, the blue ones from China.

|

|

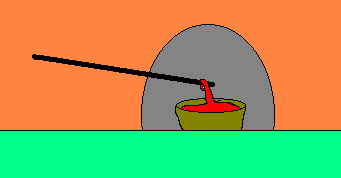

Furnace wound beads often have a thin black perforation deposit. It is a thin layer of iron oxide from the mandrel. The bead is from Pakistan.

|

|

|

|

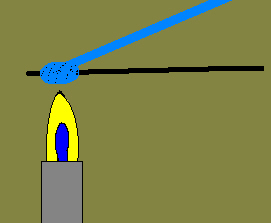

Lamp wound beads often have some powdery perforation deposit because a separator is needed to remove the bead from the wire. These are Japanese. Venetian beadmakers glued the separator to the wire, so their beads have little or no deposit.

|

|

_________________________________________________

Small Bead Businesses | Beading & Beadwork | Ancient Beads | Trade Beads

Beadmaking & Materials | Bead Uses | Researching Beads | Beads and People

Center for Bead Research | Book Store | Free Store | Bead Bazaar

Shopping Mall | The Bead Auction | Galleries | People | Events

The Bead Site Home | Chat Line | Contact Us | Site Search Engine | FAQ

|